At the meltmedia office we're making a video podcast once a week. Our design team made a cool backdrop for the little studio area we use. It's a big-ass inkjet direct-print on a full 8' by 4' sheet of foam core. As you can guess, it was a bit floppy and needed some kind of support behind it. It also needed to be lightweight because we wanted to be able to hang it on the whiteboard behind us so we could easily remove it and replace it when we needed the whiteboard. I looked around the garage and all I had that was long enough was an 8' 2x4. So, the entire frame is made from that single pine 2x4. I ripped three 1" strips from it. to get the top, bottom and sides. The sides are just a long piece cut in half.

Since this was going on the back of the backdrop, not in view, I wasn't real careful about the quality of the cuts, but it was still pretty good. I glued and nailed the pieces together.

Next, I took the strip that was leftover from ripping the other three, which turned out to be less than a quarter inch, and cut 18" pieces from it and cut the ends at 45º.

I checked sloppily for squareness by measuring the distance of the two opposite corners. Once I got it mostly square, I glued and nailed the pieces onto the corners.

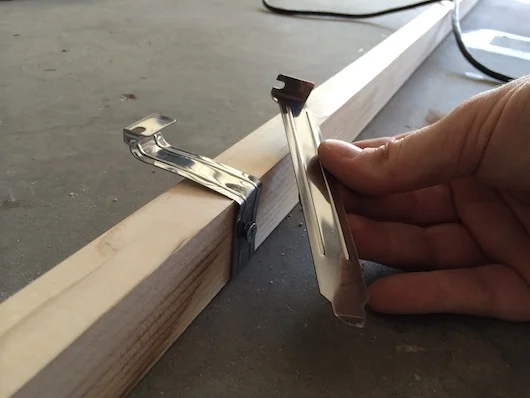

I have all sorts of weird leftover parts from things in my past. One little bundle of metal parts is a pile of old PC expansion card slot covers. I bent those into hooks for the frame.

I screwed two of those homemade hooks onto the top of the frame about 24" in from the sides.

The last piece I added was a strip of poplar I had laying around to keep the center of the gangly frame from sagging too much.

The strip is only there to keep the bottom of the frame the same distance from the top. It doesn't really carry a lot of load in the frame.

The last step was to haul the frame to the office and glue it to the back of the backdrop. I used some 3M® 55 spray adhesive. That crazy stuff dries fast in the Arizona heat and dryness, so I had a buddy from work help me spray the parts and run them back into the office to smash them together. I put some Ikea chairs on the corners and a couple of other heavy objects in the middles of the sides of the frame to keep the two layers of adhesive together while it dried.

The hooks worked out perfectly.

The frame and board is lightweight and the hooks hold it solidly.

The finished product turned out great, works perfectly and will hopefully serve us well throughout the series of videos.