It was pretty easy to build a large wood frame shed or mini workshop, actually. Used wood framing that is 24-inch-on-center, salt box roof design, and a cool storage unit type of steel roll-up door.

Fitness Tracker "Tester" (& Pokemon Incubator?)

FitBit Contest at meltmedia - No Cheat-O-Matic

The last two FitBit competitions at the office didn't work out for me as far as timing. I was injured both times, so I build a machine to run the heck out of my FitBit! This time around, however, I'm healthy and kicking butt! This article is just my thoughts on our FitBit competitions and FitBit cheating.

Designing a New Man Cave and Workshop

We're moving! Not real far, but we're moving. My commute to the office is about 30 minutes, which isn't horrible, but in a 5.7-liter V8 truck, it's not as cheap as it could be, either. My wife's commute is an hour, poor thing. BUT, we happened upon a great house sitting on 0.8 acres of land centrally located in the metro Phoenix area only ten minutes away from my office and 15 minutes away from my wife's.

I highlighted the 0.8 acres of land because... DETACHED WORKSHOP!!!

Fitbit Cheat-O-Matic 2: 3D Printed Mechanical Simplicity

I was watching old engineering videos from 1939 on YouTube one day and saw a cool demonstration of a cam and follower in a machine of unknown purpose. I realized then that I could make a very simple contraption using 3D printing and a geared DC motor to shake a Fitbit up and down very easily. It could be super-simple to assemble, cheap to print all the parts but the motor and probably run off a simple 12V wall wart power supply.

Easy DIY PVC Poolside Towel Rack

With great pool comes great towel mess! This is a simple DIY project that uses inexpensive PVC pipe, a few screws and a shade umbrella stand to make a very practical towel tree for summertime poolside organization. I think it took me all of an hour, maybe two, to assemble and paint. Total cost, a hair over $50. If you don't paint it, less than $50.

Rescue a Little Critter from Sticky Board Trap

An unintended consequence of placing glue traps around the garage: A desert spiny lizard, which is very beneficial to our yard as a pest control device, stuck itself to one of our "research" glue traps. These glue traps were intended to catch the various little bugs that might wander in through the space between the garage door and the door frame.

This is the short story about how I rescued her with a drizzle of olive oil.

CAD: Now My Most Important Maker Tool

I have always engineered my projects by the seat of my pants. I will get an idea and I just start plugging things together in the workshop or man cave. At best, I will breadboard parts of a larger electronics project to make sure the ideas work, but mostly, I just build on-the-fly. Grab a piece of wood and throw it on the bandsaw, try the fit, trim it there, sand it there and then glue and screw. Quick and easy. Just me, the material and the tools.

Certain projects I'm working on are getting closer to possible products or kits. That means I'll need a more well-defined plan that others can work with in helping to produce these things. That means CAD!

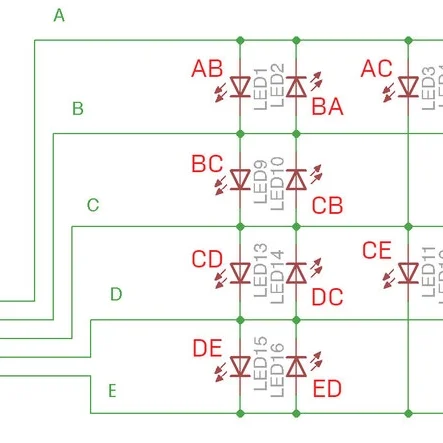

Charlieplexing MORE LEDs (20, to be exact)

A while back I wrote an article for MAKE's blog about Charlieplexing LEDs with an AVR or Arduino. I just wanted to drop this quick update on how to 'plex 20 LEDs. I've now had TWO different people ask about doing more than 12 LEDs.

I created a Gist on GitHub to control the LEDs and a matching and labeled schematic to demonstrate 20 Charlieplexed LEDs, but I've not actually tested the setup or the code (FYI).

Dartboard Backstop from Office Corkboard

Playing darts is fun! Patching drywall behind and around a dartboard is not fun.

To protect the wall around our dartboard, I wanted to build a cool, framed something-er-other that would safely catch stray darts, hold darts that weren't being used, catch falling darts that might not hang onto the dartboard or the backstop (using a shelf or a net or something) and maybe have a scoreboard. I also wanted the style of the backstop to match our pool table, which is an ornate, ebony-kinda-finish with red felt.